电阻层析成像模块

基于电阻率层析成像的三维旋喷灌注加固形态监测

Research on electrical resistance tomography of Monitoring of 3D rotary jet grouting reinforcement morphology

背景介绍

Background

本案例利用电阻层析成像和三维打印技术对旋喷灌注桩的三维几何形态进行物理模拟和实验监测。首先,通过使用三维打印技术对碳晶导电增强材料进行类旋喷桩的模型构造,其次使用电阻层析成像系统对固化作用后的类旋喷桩进行重构建模,利用粉末三维打印技术构建小型加固试样进行加固体几何形态和力学特性研究。通过实验研究,得到了室内工况下旋喷灌注桩三维加固形态和加固力学特性的物理实验数据,探索了电阻层析成像和三维打印技术在岩土加固研究中的应用,为后续的三维加固形态数学建模和数值模拟分析提供了初步的验证数据。

This case utilizes electrical resistance tomography and 3D printing technology to physically simulate and experimentally monitor the three-dimensional geometric shape of rotary sprinkler irrigation piles. Firstly, a three-dimensional printing technology was used to construct a model of carbon crystal conductive reinforcement material similar to rotary jet grouting piles. Secondly, a resistance tomography system was used to reconstruct and model the solidified rotary jet grouting piles. Finally, a small reinforced sample was constructed using powder three-dimensional printing technology to study the solid geometry and mechanical properties. Through experimental research, physical experimental data on the three-dimensional reinforcement morphology and mechanical characteristics of rotary jet grouting piles under indoor working conditions were obtained. The application of electrical resistance tomography and three-dimensional printing technology in geotechnical reinforcement research was explored, providing preliminary validation data for subsequent mathematical modeling and numerical simulation analysis of three-dimensional reinforcement morphology.

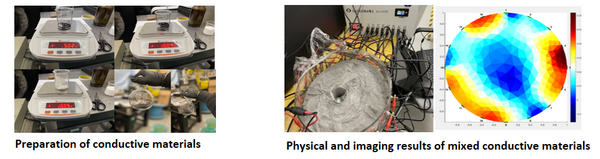

关键技术1:碳精粉混合导电材料制备

Preparation of carbon fine powder mixed conductive materials

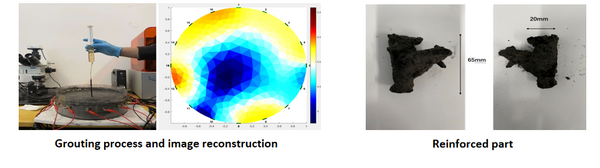

关键技术2:三维旋喷灌注加固体图像重构

3D rotary jet grouting with solid image reconstruction

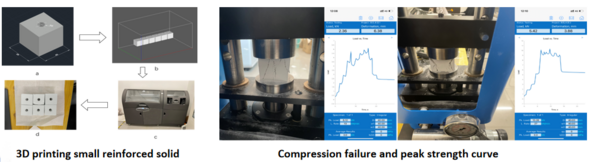

关键技术3:三维粉末打印的小型加固形态和力学性能研究

Research on small reinforcement morphology and mechanical properties of 3D powder printing

![聚酰胺粉 [柱层析用,高分离性能] 60-100目/80-120目/100-200目](https://p-06.caigou.com.cn/135x120/2024/7/2024071513085253637.jpg)